Welcome to Club SAITO !

One thing about those deflectors though, they tend to pop off if they are not really tight. I used a small screw and attached it that way along with the cable tie. Works really good.

My Feedback: (3)

Interesting about the Christian Traders exhaust. The big question is durability. All that I've seen crack soon. It would be a good thing to have access to flex exhaust pipes that last.

Join Date: Jun 2010

Location: RIO, GREECE

Posts: 94

Likes: 0

Received 0 Likes

on

0 Posts

Hi,

I have bought a second hand FA65 without muffler. Can anyone give me the basic dimensions that are required to manufacture the muffler (length, outer diameter, inner diameters, etc)?

Any help will be greatly appreciated.

StZ

I have bought a second hand FA65 without muffler. Can anyone give me the basic dimensions that are required to manufacture the muffler (length, outer diameter, inner diameters, etc)?

Any help will be greatly appreciated.

StZ

Senior Member

Join Date: Apr 2010

Location: Cairns, AUSTRALIA

Posts: 1,053

Likes: 0

Received 0 Likes

on

0 Posts

blw, those exhausts work on big as well as small engines and the only failures I have seen are in the joing of the pipe to the muffler (usually an agricultural thing). The pipes are very similar to the Saito ones but are but either to commercial sizes or on special order and I think (but don't hold me to it) they will even attach the muffler for you. For a fee of course.

Senior Member

I had a flex pipe do that on my PT-19 with an inverted FA-150. I silver brazed a short section of a brass bottle neck cartridge case inside the broken end & ran the exhaust for quite some time afterward.

My advise is to shorten the flex pipe as much as possible, then remove & silver baze the end back on.

Senior Member

Join Date: Apr 2010

Location: Cairns, AUSTRALIA

Posts: 1,053

Likes: 0

Received 0 Likes

on

0 Posts

Good advice Snr Telemaster would fit with what I observed on a DLE 30 at the field. Now for the "interested" What is wrong with this statement 20:1 is the same as having 18% oil content for a gas engine.

My Feedback: (2)

Last edited by JNorton; 11-27-2014 at 05:50 AM.

Join Date: Jun 2010

Location: RIO, GREECE

Posts: 94

Likes: 0

Received 0 Likes

on

0 Posts

You biggest problem will be getting the nut and pipe that threads into the exhaust port. Nothing about the muffler itself is critical. It is just a hollow tube. If you somewhat duplicate the size of the muffler from pictures you'll be fine. Don't forget the pressure nipple at the beginning of the muffler

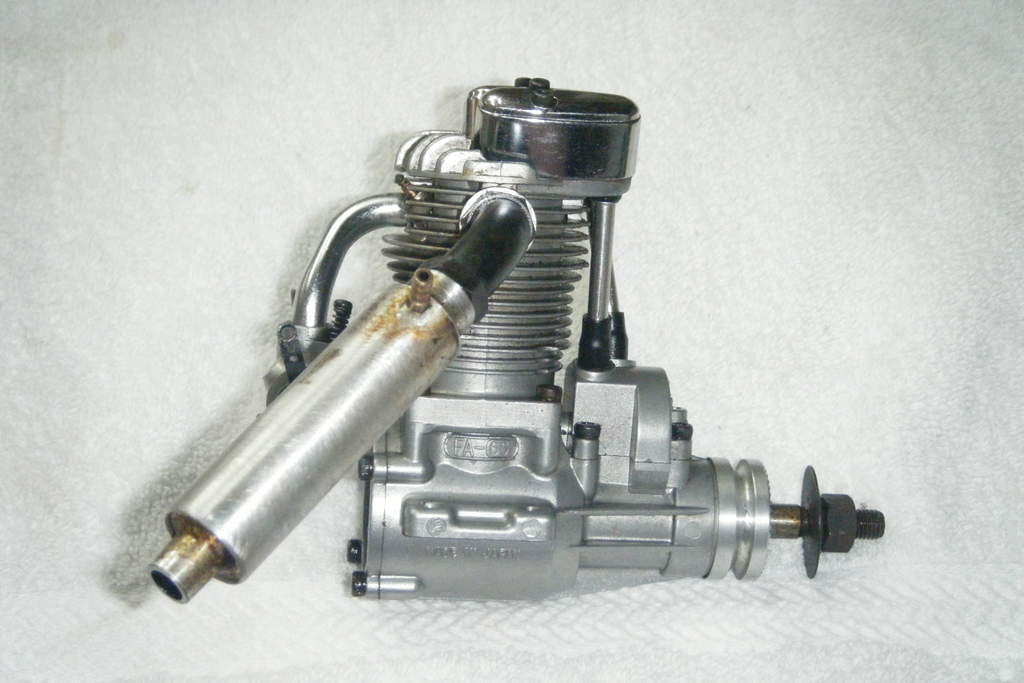

I have the nut and pipe that goes into the head. I also have something similar to an exhaust on the engine. Everything works fine. Endless idle and good transition. Problems start when the plane goes towards vertical. The engine just stops. Start it again everything is fine until you pick up the plane and point it towards the sky. It sounds like there is not enough fuel going to the engine. Maybe the back pressure is not enough to deliver fuel against gravity. I attach a photo for your comments.

Thanks

StZ

Sounds more like a lean condition than anything. If tank is setup correctly and the fuel lines are tight, then you are leaning out on vertical. One of the tests to verify proper carb settings is to point the nose straight up at WT and see if it stays running, and if you have a helper, transition between idle and WOT and back, and if it stays running, you got it nailed.

My Feedback: (1)

Join Date: Oct 2002

Location: Great Falls, MT

Posts: 931

Likes: 0

Received 0 Likes

on

0 Posts

Hard to tell from the pic, it looks like the tubing may be too big for the muffler nipple?? Other than that, what happens when you richen the high speed needle?

Join Date: Jun 2010

Location: RIO, GREECE

Posts: 94

Likes: 0

Received 0 Likes

on

0 Posts

Sounds more like a lean condition than anything. If tank is setup correctly and the fuel lines are tight, then you are leaning out on vertical. One of the tests to verify proper carb settings is to point the nose straight up at WT and see if it stays running, and if you have a helper, transition between idle and WOT and back, and if it stays running, you got it nailed.

Forgot to mention that engine stops within 2-4 seconds after pointing to vertical. All adjustments are done when plane is horizontal and then lifting upwards to see the effect.

Join Date: Jun 2010

Location: RIO, GREECE

Posts: 94

Likes: 0

Received 0 Likes

on

0 Posts

Changing the h.s.n has no effect. The engine always stops when vertical. That is why my question concerns the exhaust. It seems to be the only one that could cause the problem.

Tune it with half a tank, and set your LSN a tad richer too. Stopping 2-4 seconds after going vertical is an indication of one of two things. Lack of Fuel due to no back pressure or vacuum, or lack of fuel from running lean. If you have no changes on the HSN, open the LSN up a bit and see if that helps. Try this, after running the engine for a while, pull the line off the muffler, and refill the tank the way you normally do and see if you get smoke coming out the pressure line of the tank. If you see no smoke, chances are you are not pressurizing the tank from the muffle, maybe the nipple is clogged.

Is your tank plumbed as 2 line, or 3 line, and do you have a fill jack? Also check the fuel line for bubbles when running, especially when you put the nose up.

Is your tank plumbed as 2 line, or 3 line, and do you have a fill jack? Also check the fuel line for bubbles when running, especially when you put the nose up.

Join Date: Jun 2010

Location: RIO, GREECE

Posts: 94

Likes: 0

Received 0 Likes

on

0 Posts

Tune it with half a tank, and set your LSN a tad richer too. Stopping 2-4 seconds after going vertical is an indication of one of two things. Lack of Fuel due to no back pressure or vacuum, or lack of fuel from running lean. If you have no changes on the HSN, open the LSN up a bit and see if that helps. Try this, after running the engine for a while, pull the line off the muffler, and refill the tank the way you normally do and see if you get smoke coming out the pressure line of the tank. If you see no smoke, chances are you are not pressurizing the tank from the muffle, maybe the nipple is clogged.

Is your tank plumbed as 2 line, or 3 line, and do you have a fill jack? Also check the fuel line for bubbles when running, especially when you put the nose up.

Is your tank plumbed as 2 line, or 3 line, and do you have a fill jack? Also check the fuel line for bubbles when running, especially when you put the nose up.

It should be that there is low back pressure to the tank from the muffler. When it dies rpm do not change. If it was leaning out, the rpms would increase somewhat, they do not!

The muffler nipple is not clogged and I cannot see any bubbles going to the carb. I will try your suggestion and I will let you know.

Senior Member

Join Date: Apr 2010

Location: Cairns, AUSTRALIA

Posts: 1,053

Likes: 0

Received 0 Likes

on

0 Posts

St Z check the clunk in the tank is the correct length and also not turned back on itself. Re pressure I run most of my Saito's without tank pressure and when set up properly have no troubles no matter what the attitude. Most common fuel problem at my field over the last few weeks has been kinked pressure lines consider that as well. Easy check pull the pressure line off and operate.

Senior Member

Join Date: Apr 2010

Location: Cairns, AUSTRALIA

Posts: 1,053

Likes: 0

Received 0 Likes

on

0 Posts

Senior Member

My Feedback: (3)

StZ, some questions and a few ideas.

First off, how long are the fuel line runs between the tank and carb?

Does the behavior change depending on amount of fuel in the tank?

Have you tried this with the plane inverted? If so, any change?

Does the fuel tank have a center or top oriented outlet?

Do you have the stock muffler and tried it to see if any change? On that note, how far into your muffler do the exhaust and pressure tubes extend?

I read you do not see any bubbles, but can you spot a loss of clean fuel feed with the nose up?

Reasons for these are twofold. First is if the distance is too great between the clunk pickup and carb muffler pressure may not be enough to provide adequate head pressure to the tank. One possible quick check would be to add a check valve in that pressure line and do a quick check to see if the problem persists.

NOTE: Only do this if you are confident your tank can tolerate inflating a bit and keep the run short. At the end you will need to relieve that pressure, best done by pulling off the vent line downstream from the check valve. Watch you do not get sprayed with raw fuel as you may have considerable pressure stored in the tank.

It may seem simple, but I would second FNQFLYER in advising you to check the clunk orientation. Any sudden stoppage, including a nose over, can provide enough inertia to throw that clunk to the front of the tank, especially if low on fuel. Soft compound tubing makes that even more likely. This would definitely cause what you describe and no amount of needle fiddling will cure the problem.

As for tubing nto the muffler, I'm now into guesswork, but if either tube extends too far it may interfere with pressure wave patterns. If you look at the stock setup neither the inlet or pressure nipple protrude beyond the wall thickness and their nipple is closer to the inlet than yours. This may interfere with pulses feeding into the pressure system.

Also on that note, cannot see your outlet diameter. If too large you may not restrict the exhaust enough to build any pressure inside the muffler body at all.

In that case, I would agree you should show some signs of leaning before cutoff. If yours is as sudden as described I would again check the clunk.

Another simple check may be to have the carb line fed from a simple container other than the existing tank. Keep it at the same height and even work with an open top with no pressure to see if you still quit with a solid and reliable fuel source, (no loss of direct fuel feed you would experience if the clunk were exposed). You can vary the height of the fuel source to carb to see if any difference.

First off, how long are the fuel line runs between the tank and carb?

Does the behavior change depending on amount of fuel in the tank?

Have you tried this with the plane inverted? If so, any change?

Does the fuel tank have a center or top oriented outlet?

Do you have the stock muffler and tried it to see if any change? On that note, how far into your muffler do the exhaust and pressure tubes extend?

I read you do not see any bubbles, but can you spot a loss of clean fuel feed with the nose up?

Reasons for these are twofold. First is if the distance is too great between the clunk pickup and carb muffler pressure may not be enough to provide adequate head pressure to the tank. One possible quick check would be to add a check valve in that pressure line and do a quick check to see if the problem persists.

NOTE: Only do this if you are confident your tank can tolerate inflating a bit and keep the run short. At the end you will need to relieve that pressure, best done by pulling off the vent line downstream from the check valve. Watch you do not get sprayed with raw fuel as you may have considerable pressure stored in the tank.

It may seem simple, but I would second FNQFLYER in advising you to check the clunk orientation. Any sudden stoppage, including a nose over, can provide enough inertia to throw that clunk to the front of the tank, especially if low on fuel. Soft compound tubing makes that even more likely. This would definitely cause what you describe and no amount of needle fiddling will cure the problem.

As for tubing nto the muffler, I'm now into guesswork, but if either tube extends too far it may interfere with pressure wave patterns. If you look at the stock setup neither the inlet or pressure nipple protrude beyond the wall thickness and their nipple is closer to the inlet than yours. This may interfere with pulses feeding into the pressure system.

Also on that note, cannot see your outlet diameter. If too large you may not restrict the exhaust enough to build any pressure inside the muffler body at all.

In that case, I would agree you should show some signs of leaning before cutoff. If yours is as sudden as described I would again check the clunk.

Another simple check may be to have the carb line fed from a simple container other than the existing tank. Keep it at the same height and even work with an open top with no pressure to see if you still quit with a solid and reliable fuel source, (no loss of direct fuel feed you would experience if the clunk were exposed). You can vary the height of the fuel source to carb to see if any difference.

Last edited by Cougar429; 11-27-2014 at 03:43 PM.

If the clunk moved forward, the line would drain of fuel and show, but he said he didnt see any bubbles. Sounds like a lean condition still, and you wont always hear an RPM increase. It could also be a leaking o-ring at the carb.

Join Date: Jun 2010

Location: RIO, GREECE

Posts: 94

Likes: 0

Received 0 Likes

on

0 Posts

St Z check the clunk in the tank is the correct length and also not turned back on itself. Re pressure I run most of my Saito's without tank pressure and when set up properly have no troubles no matter what the attitude. Most common fuel problem at my field over the last few weeks has been kinked pressure lines consider that as well. Easy check pull the pressure line off and operate.

Join Date: Jun 2010

Location: RIO, GREECE

Posts: 94

Likes: 0

Received 0 Likes

on

0 Posts

If there was a leak in the carb o-ring would it not run erratic during prolonged idle?

Join Date: Jun 2010

Location: RIO, GREECE

Posts: 94

Likes: 0

Received 0 Likes

on

0 Posts

StZ, some questions and a few ideas.

First off, how long are the fuel line runs between the tank and carb?

Does the behavior change depending on amount of fuel in the tank?

Have you tried this with the plane inverted? If so, any change?

Does the fuel tank have a center or top oriented outlet?

Do you have the stock muffler and tried it to see if any change? On that note, how far into your muffler do the exhaust and pressure tubes extend?

I read you do not see any bubbles, but can you spot a loss of clean fuel feed with the nose up?

Reasons for these are twofold. First is if the distance is too great between the clunk pickup and carb muffler pressure may not be enough to provide adequate head pressure to the tank. One possible quick check would be to add a check valve in that pressure line and do a quick check to see if the problem persists.

NOTE: Only do this if you are confident your tank can tolerate inflating a bit and keep the run short. At the end you will need to relieve that pressure, best done by pulling off the vent line downstream from the check valve. Watch you do not get sprayed with raw fuel as you may have considerable pressure stored in the tank.

It may seem simple, but I would second FNQFLYER in advising you to check the clunk orientation. Any sudden stoppage, including a nose over, can provide enough inertia to throw that clunk to the front of the tank, especially if low on fuel. Soft compound tubing makes that even more likely. This would definitely cause what you describe and no amount of needle fiddling will cure the problem.

As for tubing nto the muffler, I'm now into guesswork, but if either tube extends too far it may interfere with pressure wave patterns. If you look at the stock setup neither the inlet or pressure nipple protrude beyond the wall thickness and their nipple is closer to the inlet than yours. This may interfere with pulses feeding into the pressure system.

Also on that note, cannot see your outlet diameter. If too large you may not restrict the exhaust enough to build any pressure inside the muffler body at all.

In that case, I would agree you should show some signs of leaning before cutoff. If yours is as sudden as described I would again check the clunk.

Another simple check may be to have the carb line fed from a simple container other than the existing tank. Keep it at the same height and even work with an open top with no pressure to see if you still quit with a solid and reliable fuel source, (no loss of direct fuel feed you would experience if the clunk were exposed). You can vary the height of the fuel source to carb to see if any difference.

First off, how long are the fuel line runs between the tank and carb?

Does the behavior change depending on amount of fuel in the tank?

Have you tried this with the plane inverted? If so, any change?

Does the fuel tank have a center or top oriented outlet?

Do you have the stock muffler and tried it to see if any change? On that note, how far into your muffler do the exhaust and pressure tubes extend?

I read you do not see any bubbles, but can you spot a loss of clean fuel feed with the nose up?

Reasons for these are twofold. First is if the distance is too great between the clunk pickup and carb muffler pressure may not be enough to provide adequate head pressure to the tank. One possible quick check would be to add a check valve in that pressure line and do a quick check to see if the problem persists.

NOTE: Only do this if you are confident your tank can tolerate inflating a bit and keep the run short. At the end you will need to relieve that pressure, best done by pulling off the vent line downstream from the check valve. Watch you do not get sprayed with raw fuel as you may have considerable pressure stored in the tank.

It may seem simple, but I would second FNQFLYER in advising you to check the clunk orientation. Any sudden stoppage, including a nose over, can provide enough inertia to throw that clunk to the front of the tank, especially if low on fuel. Soft compound tubing makes that even more likely. This would definitely cause what you describe and no amount of needle fiddling will cure the problem.

As for tubing nto the muffler, I'm now into guesswork, but if either tube extends too far it may interfere with pressure wave patterns. If you look at the stock setup neither the inlet or pressure nipple protrude beyond the wall thickness and their nipple is closer to the inlet than yours. This may interfere with pulses feeding into the pressure system.

Also on that note, cannot see your outlet diameter. If too large you may not restrict the exhaust enough to build any pressure inside the muffler body at all.

In that case, I would agree you should show some signs of leaning before cutoff. If yours is as sudden as described I would again check the clunk.

Another simple check may be to have the carb line fed from a simple container other than the existing tank. Keep it at the same height and even work with an open top with no pressure to see if you still quit with a solid and reliable fuel source, (no loss of direct fuel feed you would experience if the clunk were exposed). You can vary the height of the fuel source to carb to see if any difference.

I have the nut and pipe that goes into the head. I also have something similar to an exhaust on the engine. Everything works fine. Endless idle and good transition. Problems start when the plane goes towards vertical. The engine just stops. Start it again everything is fine until you pick up the plane and point it towards the sky. It sounds like there is not enough fuel going to the engine. Maybe the back pressure is not enough to deliver fuel against gravity. I attach a photo for your comments.

Thanks

StZ

Thanks

StZ

Hope your Thanksgiving was Happy, and best wishes for a merry Chriastmas to you and yours.

Sincerely, RichardCub Brotherhood #187; Sig 1/4, H9 100 inch (Gen 1), GB Anniv Cub

Club Saito #635; Saito 56, 100, 120abc, 130T, 180

Kadet Brotherhood #96; Mk 1 Kadet, Kadet Junior,

Sig Kougar, Sig 1/4 Cub, Sig 1/4 Spacewalker II